Use combination drenches to slow drench resistance

To slow the development of drench resistance in sheep worms, it is now considered best practice to use drench groups in combination rather than the traditional approach of rotating drenches.

When it comes to managing worms in sheep, combination drenches are one of the most valuable tools in your toolkit. However, often the questions ‘but why is this the case?’ and ‘if I use a combination drench, won’t the worms develop resistance to all the actives in the combination?’ come up.

The traditional approach of rotating drenches is no longer considered best practice, with recent research advances noting that rotation itself will not delay the development of resistance.

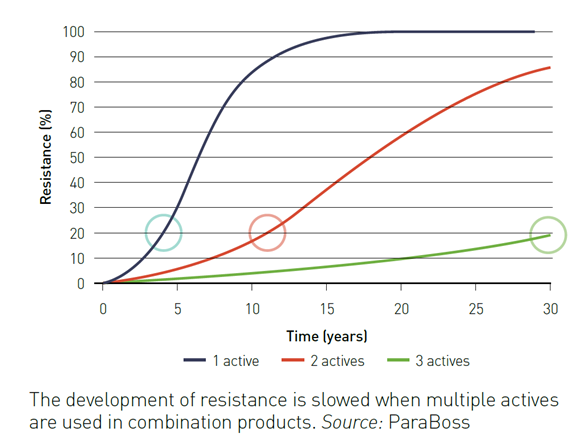

Using drench groups in combination has a much greater effect in slowing the development of resistance and is recommended best practice.

This is somewhat dependent on your starting point in terms of efficacy of the actives in the combination on the worms in your sheep. The key here is not to start using combinations containing single actives which are not effective on your place.

A drench is considered effective if it controls >98% of the worms present. Once you have any level of ineffective single actives, your starting point is adjusted.

The graph below illustrates the development of resistance over time. The green line (a three active combination product) shows a much longer delay in the development of resistance when compared with single or dual active products.

This is not the ‘green light’ for using the same product or group of actives for the next 30 years! Rather, using knowledge and information is key here.

How does this work?

The genes that make worms resistant to different chemical groups/actives are different. Using a combination of actives means that less worms survive as the chance of a worm having resistant genes to several groups/actives is much lower than to just a single group/active. Therefore, the likelihood of the combination product being effective is greater, because if one active doesn’t kill them, the other will.

It is important to note that some available products contain more than one active but are not combination drenches. These are the products that contain actives that target different types of worms – one active might target roundworms, and the other active targets tapeworms – so they need to be considered as single actives because resistance to and effectiveness of chemical actives is on a worm-by-worm basis.

Key steps in minimising the onset of drench resistance

Whilst a complex topic, there are several simple steps you can take to reduce the risk of developing resistant worms in your flock:

- Know your enemy – what worms are present and what are you targeting? Use worm egg counts (WEC) to quantify what burdens are present, and larval differentiation to identify which species are present and when. Regular WEC testing is important. Worm species present may differ at different times of the year.

- What is your threshold for different classes of sheep by worm type? Check out the ParaBoss Drench Decision Guides for your WormBoss region at paraboss.com.au/tools.

- Calibrate your drenching equipment and ensure it is always in excellent working order. Under-dosing leads to accelerated development of resistance and over-dosing is simply costly and may lead to residue issues or toxicity.

- ALWAYS follow the label directions – including drenching to the heaviest in the mob to avoid under-dosing. If there is a large variation in weights in the mob, split the mob into heavies and lights. Use scales to be accurate in your dosage. Check withholding periods and export slaughter intervals, along with the special instructions that pertain to the product you are using – e.g. time off feed, stress, etc.

- Follow up drenches with a WEC test 10–14 days after treatment to ensure your drench was effective. This is an economical way to be sure your efforts have achieved what you set out to do. It also gives you an early heads-up if the drench has not worked, before further production losses occur.

- Know the drench resistance status of single actives on your farm. This can be then used to calculate the rate of effectiveness of the combinations. This is done by doing a Worm Egg Count Reduction Test (WECRT, also called a fecal egg count reduction test, or drench resistance test). The combination-drench efficacy calculator can be accessed at paraboss.com.au/tools.

- Use all opportunities to minimise worm challenge to susceptible stock. Prepare low worm-risk paddocks and, where available, select rams with genetic resistance to worms (negative WEC ASBV).

Effective worm control can be tricky, as no two seasons are the same; the worms are invisible or difficult to see and can cause invisible production losses or, in extreme situations, widespread ill health or death in sheep. It is strongly recommended to seek the advice of an experienced advisor who understands worm control, along with local production details.

This article was written by AWI Extension NSW Project Manager, Megan Rogers, for the February edition of the AWI Woolgrower e-newsletter. Articles written by AWI Extension Project Managers will regularly feature in the e-newsletter. To subscribe to the e-newsletter, head to www.wool.com/subscribe.

More information: www.wormboss.com.au

This article appeared in the Autumn 2025 edition of AWI’s Beyond the Bale magazine that was published in March 2025. Reproduction of the article is encouraged.