Make your shed a shear delight

Professional and safe working conditions in shearing sheds can help woolgrowers attract and retain shearers and wool handlers, as well as improve their productivity and profitability.

AWI Chairman Jock Laurie and Rhodes Pastoral’s farm manager Michael Wright, with wool classer Jazz Piper, AWI director David Webster and shearing contractor Aaron Piper of Dinninup Shearing Services.

Professional and safe working conditions in shearing sheds can help woolgrowers attract and retain shearers and wool handlers, as well as improve their productivity and profitability.

Working conditions in sheds are seen as the primary barrier to attracting and keeping new workers in the wool harvesting industry, according to a survey of shearing contractors across Australia undertaken by AWI and the WA Shearing Industry Association (WASIA).

“The message is clear,” said AWI Chairman, Jock Laurie. “With so many alternative career options available to young people in Australia, it is vital that the wool industry ensures that working conditions in shearing sheds are as professional as possible to attract and retain wool harvesting staff.

“Woolgrowers can play their part by, for instance, having their sheep properly curfewed and presented for shearing, provide safe working conditions for wool harvesting staff, and also provide a modern and professional work environment with amenities that we as woolgrowers would expect.”

AWI has produced a range of resources to help woolgrowers improve their shearing shed and optimise the work environment for their wool harvesting staff – see page opposite.

Jock recently visited Rhodes Pastoral, a large mixed operation based at Dinninup in Western Australia’s south-west, that runs 24,000 Merino ewes.

“It was a great example of a shearing team being very happy. They were provided with good facilities and the sheep were in good order – so everything was working well,” Jock added.

“Having a very good, strong and long-term working relationship between a professional shearing team and the woolgrower is very important.”

Rhodes Pastoral’s farm manager

Michael Wright has been the farm manager at Rhodes Pastoral for the past 20 years. In his time there, Michael has seen the business grow from about 3,000 hectares of pasture to more than 16,000 hectares, and the business’s wool clip increase significantly from 140 bales of wool to 1,150 bales of wool. Their mature ewes usually cut 6-7kg of 19.5 to 20.5-micron wool.

“We have a great wool harvesting team that’s been working with us for 20 years,” Michael said.

“They live in the town and come out to us each day to shear. We present the sheep well, we have sloping catching pens, and the shed being U-shaped with a raised board helps the team harvest efficiently. All our sheds are well-maintained and have passed the SafeSheds program.

“There are amenities for the staff such as decent toilets, shower facilities, a clean kitchen, and air conditioning. The shed is their workplace, so it’s got to be a professional environment. It’s safe, friendly, with no smoking, drugs or alcohol. We have a good set of rules in the shed that are followed by staff.”

Michael is the grower representative on the Western Australia WoolTAG, a body that has a focus on wool harvesting in the state.

“Through the WoolTAG we’re trying to showcase wool harvesting as a career not just a job. We want to retain the young people that enter the industry,” he said.

“If you are a woolgrower and you want good harvesting staff, workers who want to come back to your shed, you've got to provide good facilities and a safe shed. It’s as simple as that. Poor facilities are just not on anymore; we're in the 21st century.”

Rhodes Pastoral’s shearing contractor

Aaron and Jazz Piper of Dinninup Shearing Services, along with long-term permanent classer Brett Biluta, have been wool harvesting at Rhodes Pastoral for many years.

“It’s a great set-up that Michael has there and so we are happy to keep going back. It’s a well-maintained shed; the harvesting staff can walk in there and everything will be clean and ready to go. We know we won’t have a problem with broken hinges and grating, that kind of thing,” Aaron said.

“It’s important that there is a good working relationship between the woolgrower and the shearing contractor and team. Having the contractor visit the farm prior to shearing is always a good idea so that they can work together with the woolgrower to identify and rectify any problems before the shearing team arrives.

“It’s not important to the shearing team whether the shed is a new shed. What is important is that the shed is well maintained and is a presentable and safe place to work.

“The shearing shed is our workplace and, as with any other workplace, it must have proper amenities for its workers like flushing toilets and a clean kitchen area. To attract and retain workers, woolgrowers need to make the effort and provide facilities that all other workplaces provide nowadays.”

Rhodes Pastoral’s farm manager Michael Wright is passionate about training and nurturing new talent. In February, he hosted a wool harvesting school at Rhodes Pastoral for novice shearers and wool handlers, run by four AWI-funded trainers.

AWI shearing shed safety and design resources

1. SafeSheds shearing shed safety program

SafeSheds is a best practice guide and checklists to help woolgrowers improve the safety and working conditions in their shearing sheds. It is available as an 80-page booklet, while the checklists are also available in a handy digital, interactive format.

SafeSheds is a self-assessment guide and not a formal audit. It is now being used across the country by woolgrowers and their shearing contractors to help them assess the safety of their sheds, thereby enabling the woolgrower to create a program to rectify any safety hazards, improve working conditions and comply with modern workplace standards.

Launched in November 2020, SafeSheds was developed by AWI and WASIA, with the support of industry including WoolProducers Australia, Pastoralists & Graziers WA, WAFarmers and Shearing Contractors’ Association of Australia.

2. Shed safety signage kit

The shed safety signage kit for woolgrowers to use in their woolsheds contains 36 safety signs that are printed on UV-stabilised polypropylene for durability, with pre-drilled holes for easy installation. The kit also includes guidance notes to assist in the proper location and installation of the signs.

Developed and produced by WASIA, with support from AWI, these signs meet Australian Standards and legislative requirements in all Australian states and will help woolgrowers meet occupational health and safety obligations.

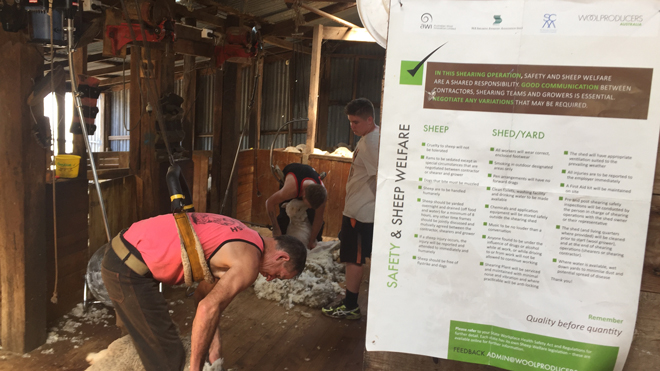

3. Safety and sheep welfare poster

A ‘code of conduct’ poster is available from AWI that can help woolgrowers set standards for their entire shearing team – regarding animal welfare, workplace health and safety and the prohibition of drug use. It can be a point of reference for everyone in the shed and help ensure they are all on the same page.

The poster is a joint initiative between AWI, Shearing Contractors’ Association of Australia, WASIA and WoolProducers Australia.

4. AWI Shearing Shed Design

AWI’s Shearing Shed Design is a result of AWI and a working group of woolgrowers and shed staff in 2019 designing a shearing shed which addresses worker safety and animal welfare considerations, while also achieving improved shed efficiency and good wool quality outcomes.

The design was developed following extensive industry consultation with some of the most experienced shearers, wool handlers, classers and woolgrowers from across Australia. Multiple trials led to refinements and a final design.

The internal fit-out has been designed to have its own structural integrity so it can be built within any suitable pre-existing shed. The builder or contractor will be able to build as it is designed or extract certain elements of the AWI design to suit specific on-site requirements. Dozens of sheds have now been built across the country using the AWI design.

5. AWI’s shearing shed design considerations guide

Published in December 2021, this 32-page guide was produced by AWI to provide woolgrowers with an outline of considerations when renovating or designing shearing sheds. It covers (1) in-shed pens, (2) shearing board, (3) wool room, (4) general design and construction, and (5) equipment.

More information:

This article appeared in the June 2023 edition of AWI’s Beyond the Bale magazine. Reproduction of the article is encouraged.